In today’s fast-paced, innovation-driven world, businesses across industries are seeking highly precise, efficient, and cost-effective manufacturing solutions. Custom CNC machining services have become an indispensable tool for companies looking to produce high-quality parts and prototypes with superior accuracy. From aerospace and automotive to medical devices and consumer electronics, CNC machining offers a level of flexibility and precision that few other manufacturing methods can match.

In this blog post, we’ll explore what custom CNC machining service are, the benefits they offer, and how they are transforming modern manufacturing.

What is Custom CNC Machining?

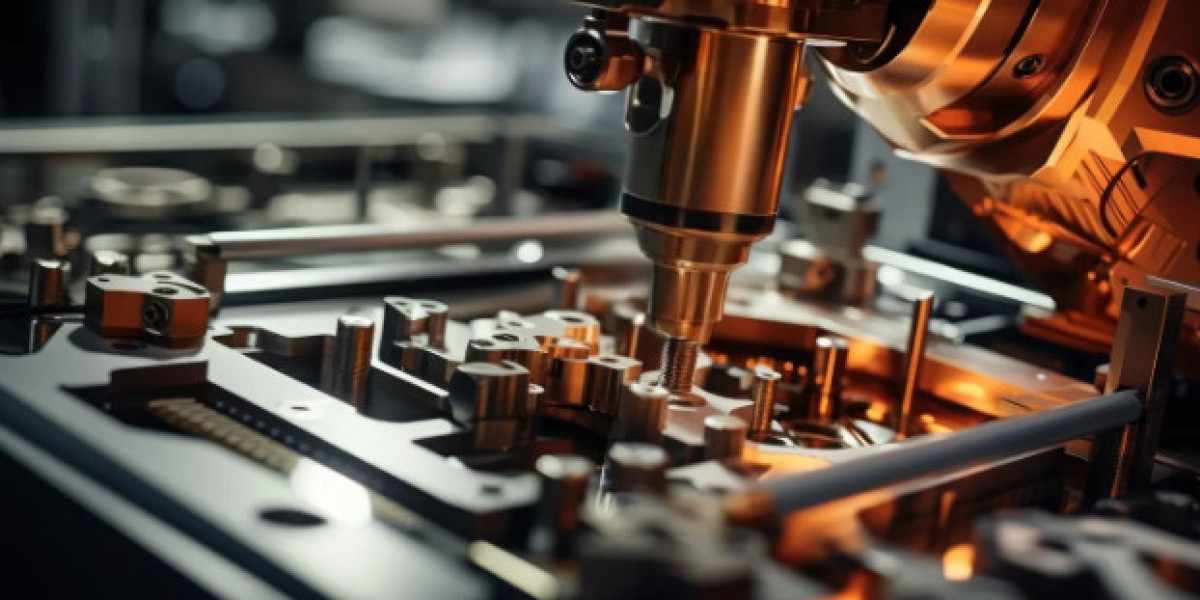

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control the movement of factory tools and machinery. CNC machines can precisely shape and cut materials such as metals, plastics, and composites to create complex parts. These machines can perform various operations, including drilling, milling, turning, and grinding, ensuring that every part is manufactured to exact specifications.

A custom CNC machining service offers tailored solutions based on the specific needs of a project. Whether creating intricate prototypes, producing low-volume batches, or machining custom parts, these services are highly adaptable and can cater to a wide range of requirements. Clients provide detailed CAD (Computer-Aided Design) files or technical drawings, which the CNC machines then use to manufacture the desired part.

Benefits of Custom CNC Machining Services

1. Unmatched Precision and Accuracy

One of the most significant advantages of CNC machining is the ability to achieve extremely high precision and accuracy. CNC machines can work with tolerances as tight as a few microns, ensuring that each part is produced exactly to the specified dimensions. This precision is especially critical in industries such as aerospace, medical devices, and automotive manufacturing, where even minor deviations can result in part failure or safety issues.

Because CNC machines are computer-controlled, human error is minimized, leading to consistent and repeatable results with each production run. This high level of precision makes CNC machining ideal for projects that require complex geometries or intricate designs.

2. Versatility and Material Flexibility

Custom CNC machining services can handle a wide range of materials, from metals like aluminum, stainless steel, and titanium to plastics such as ABS, polycarbonate, and nylon. This versatility allows businesses to select the ideal material for their specific application, whether they need parts with high strength, heat resistance, or electrical conductivity.

CNC machines are also capable of performing multiple operations on a single machine, reducing the need for multiple setups and increasing efficiency. From milling and turning to drilling and tapping, CNC machining can handle various processes, making it a one-stop solution for creating custom parts.

3. Rapid Prototyping and Product Development

In the product development cycle, time is often of the essence. Custom CNC machining services excel at rapid prototyping, enabling businesses to quickly create functional prototypes for testing and evaluation. The speed at which CNC machines can produce parts—combined with their precision—helps businesses shorten their product development timelines and bring products to market faster.

Additionally, CNC machining allows for easy adjustments and modifications to prototypes. Engineers and designers can make changes to the digital design and have new iterations manufactured quickly, facilitating faster design improvements and validation.

4. Cost-Effective for Low-Volume Production

While traditional manufacturing methods such as injection molding are cost-effective for high-volume production, they require expensive molds and tooling, making them less suitable for low-volume runs. CNC machining, on the other hand, doesn’t require special tooling, making it more economical for smaller quantities or custom, one-off parts.

For businesses looking to produce low- to medium-volume parts without investing heavily in expensive molds or setup costs, CNC machining offers a cost-effective alternative. The ability to create custom parts without additional tooling costs makes CNC machining especially attractive for startups, prototyping, and niche applications.

5. Custom Finishes and Post-Processing

In addition to producing precise parts, custom CNC machining services often provide a variety of finishing and post-processing options. These can include surface treatments such as anodizing, powder coating, sandblasting, and polishing to enhance the appearance, durability, or functionality of the final product.

This post-processing flexibility is particularly beneficial for industries like consumer electronics or medical devices, where aesthetics and functionality are equally important. By offering custom finishes, CNC machining services ensure that the final product meets both the technical and visual requirements of the project.

Applications of Custom CNC Machining Services

Custom CNC machining services are used across a wide range of industries due to their versatility and precision. Some of the key applications include:

- Aerospace: Precision-engineered parts such as turbine blades, engine components, and structural components are manufactured using CNC machining for their high accuracy and performance under extreme conditions.

- Automotive: Custom CNC machining is used to create engine parts, transmission components, and custom aftermarket parts, ensuring that every part meets the stringent demands of automotive applications.

- Medical Devices: From surgical instruments to prosthetics and medical implants, CNC machining ensures that medical components are manufactured with exacting precision and meet the required biocompatibility standards.

- Consumer Electronics: CNC machining is used to produce enclosures, casings, and internal components for smartphones, tablets, and other electronic devices.

- Industrial Equipment: CNC machining services are used to produce custom parts for machinery, tools, and equipment used in manufacturing, construction, and other industrial applications.

Custom CNC machining services Manufacturing Services China offer unparalleled precision, versatility, and speed, making them an essential tool for modern manufacturing. Whether you need to create a functional prototype, produce custom parts for specialized applications, or manufacture low-volume production runs, CNC machining provides a cost-effective, reliable, and scalable solution.